What Are the Raw Materials for Construction? A Practical Guide to Common Building Inputs

Dec, 29 2025

Dec, 29 2025

Construction Material Selector

Find the Best Materials for Your Project

This tool helps you select appropriate construction materials based on your specific project needs, climate, budget, and sustainability goals.

When you look at a new house, a bridge, or a skyscraper, you’re seeing the end result. But behind every structure are the raw materials that made it possible. These aren’t fancy finishes or smart tech-they’re the basic building blocks pulled from the earth, forests, and factories. Knowing what goes into construction isn’t just for engineers or contractors. If you’re planning a home project, buying land, or even just curious about how things are built, understanding these materials helps you ask better questions and avoid costly mistakes.

Concrete: The Backbone of Modern Construction

Concrete is everywhere. It’s in your driveway, the foundation of your neighbor’s house, and the supports under highways. It’s made from four simple things: cement, water, sand, and crushed stone or gravel. Cement, often Portland cement, is the glue. When mixed with water, it starts a chemical reaction called hydration that hardens over days and weeks. The sand and gravel give it body and strength.

Most residential projects use standard concrete with a compressive strength of 20-30 MPa. For heavy-duty uses like bridges or high-rises, engineers mix in additives like fly ash or silica fume to boost durability. You won’t see these additives on a bag at the hardware store, but they’re standard in commercial work. Concrete’s biggest advantage? It’s cheap, fireproof, and lasts decades if mixed and poured right. Its biggest flaw? It cracks under tension-so it’s almost always paired with steel rebar.

Steel: Strength in Bars and Beams

Steel is what lets buildings reach higher than ever before. It’s made from iron ore, coal, and limestone melted in a blast furnace, then refined into different grades. In construction, you’ll mostly see two types: reinforcing bar (rebar) and structural steel sections like I-beams and channels.

Rebar is the steel rods embedded in concrete. Without it, concrete would crack under weight or earthquake stress. Structural steel shapes form the skeleton of office towers and warehouses. They’re prefabricated, lifted into place with cranes, and bolted or welded together. Steel doesn’t rot, resist pests, or burn easily. But it can rust if not protected, and it expands when hot-something builders have to account for in long spans or hot climates.

Recycled steel makes up over 80% of new steel production globally. That means most of the steel in your local school or shopping center was once a car, appliance, or old building. It’s one of the most recycled materials on Earth.

Wood: The Natural Choice for Homes

Wood is still the most common material for houses in North America, Australia, and parts of Europe. In New Zealand, where timber is abundant, nearly 90% of new homes are framed with wood. The main types used are softwoods like pine, spruce, and fir-grown fast in managed forests and kiln-dried for stability.

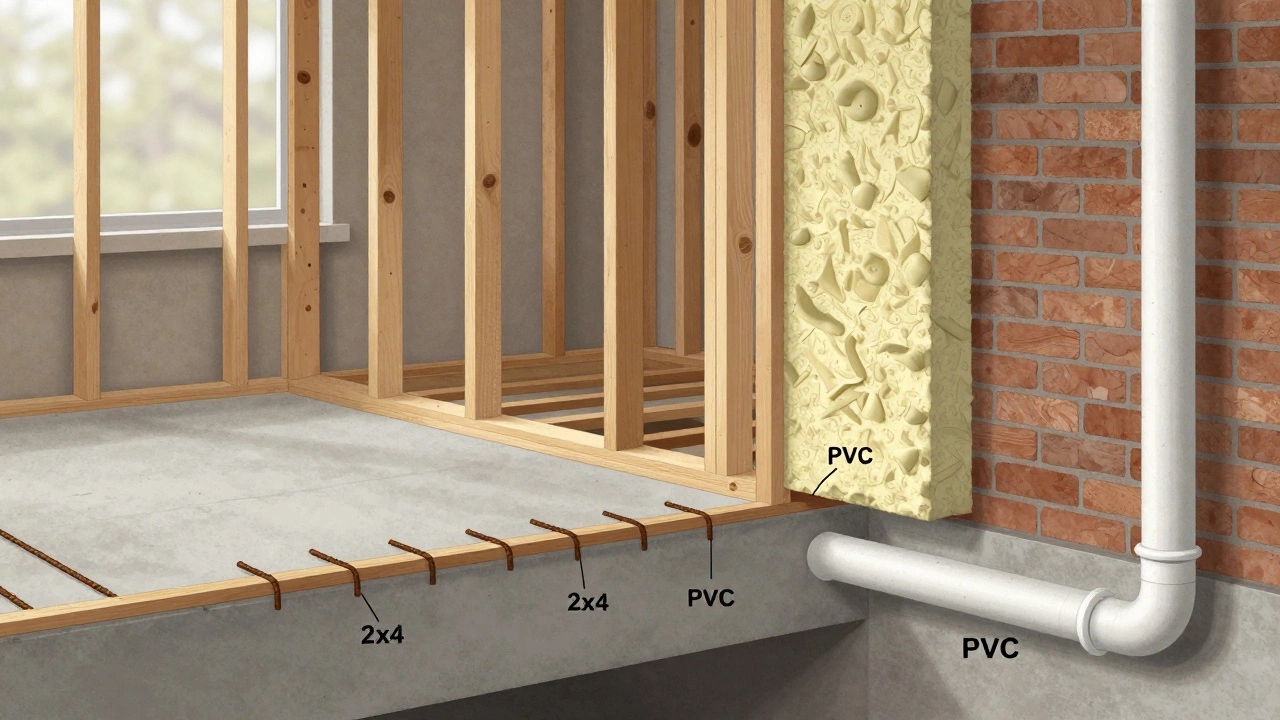

Dimensional lumber (2x4s, 2x6s) forms walls and floors. Engineered wood products like I-joists and OSB (oriented strand board) are replacing solid timber in many areas because they’re more consistent and use smaller trees. Hardwoods like oak or jarrah are used for flooring, cabinetry, and trim. They’re durable but expensive and slower-growing.

Wood is renewable, easy to cut and nail, and has good insulation properties. But it’s vulnerable to moisture, termites, and fire. That’s why treated lumber-wood soaked in preservatives like ACQ or copper azole-is required for anything touching the ground or exposed to weather. Always check the stamp on the end of a board: it tells you the grade, species, and treatment type.

Bricks and Blocks: Durable Walls That Last

Bricks have been used for over 9,000 years. Today, they’re still a top choice for exterior walls and fireplaces. They’re made from clay or shale dug from the ground, shaped into blocks, and fired in kilns at over 1,000°C. The result? Hard, dense, and weather-resistant.

Common bricks are red or brown and used for visible walls. Engineering bricks are darker, denser, and used where strength matters-like foundations or retaining walls. Concrete blocks, or CMUs (concrete masonry units), are larger, cheaper, and often used behind brick veneer or for garage walls. They’re hollow, which makes them lighter and easier to insulate.

Bricks don’t need paint or finish. They age well and hold up against wind and rain. But they’re heavy, require skilled labor to lay, and aren’t great for insulation on their own. That’s why modern brick homes often include a layer of foam insulation behind the brick.

Aggregates and Fill Materials: The Hidden Support

Most people don’t think about the dirt under their feet-but it’s critical. Aggregates like sand, gravel, and crushed rock are the bulk of concrete and asphalt. They’re also used as base layers under driveways, patios, and foundations.

For foundations, contractors dig down and fill the trench with compacted gravel or crushed stone. This drains water away and prevents shifting. In road construction, layers of different-sized aggregates are compacted to create a stable base. In landscaping, decorative gravel or river rock is used for paths and drainage.

Not all dirt is equal. Clay expands when wet and shrinks when dry-bad for foundations. Sandy soil drains well but doesn’t hold much weight. Builders test soil before pouring anything. If it’s unstable, they bring in engineered fill: a mix of gravel, sand, and crushed stone designed to settle evenly and support heavy loads.

Plastics and Synthetic Materials: The New Kids on the Block

Plastics used to be just for pipes and insulation. Now they’re in windows, roofing, flooring, and even structural panels. PVC (polyvinyl chloride) is the most common-it’s used for drain pipes, window frames, and siding because it doesn’t rot, needs no paint, and resists moisture.

Composite decking, made from recycled plastic and wood fibers, is replacing pressure-treated wood in patios. It doesn’t splinter, fade, or need sealing. Foam insulation boards, like EPS (expanded polystyrene) and XPS (extruded polystyrene), are now standard under slabs and in walls. They’re lightweight, easy to install, and offer much better insulation than old fiberglass batts.

These materials aren’t natural, but they’re designed to last longer and use fewer resources over time. Many are made from recycled content. Still, they’re not biodegradable. That’s why recycling programs for construction plastics are growing, especially in places like New Zealand and the EU.

Glass and Metals: Finishes That Matter

Glass isn’t a structural material, but it’s essential in modern buildings. Float glass is the clear, flat kind used in windows. Tempered glass is four times stronger and breaks into small, safe pieces-required for doors and low windows. Laminated glass, with a plastic layer between two sheets, holds together if shattered, making it ideal for skylights and high-rise facades.

Aluminum is used for window frames, cladding, and roofing. It’s light, corrosion-resistant, and recyclable. Copper and zinc are used for roofing and gutters in high-end homes. They develop a green patina over time, which protects them from weathering. Stainless steel is used for fasteners, railings, and appliances because it doesn’t rust.

These materials don’t carry the load, but they define how a building looks and performs. Poorly installed glass can leak. Cheap aluminum can warp in heat. Choosing the right type matters more than you think.

How to Choose the Right Materials for Your Project

Not every material works for every job. Here’s how to think about it:

- Climate: In wet areas, avoid untreated wood. Use concrete or metal for foundations. In hot, dry regions, thermal mass materials like brick or stone help regulate indoor temps.

- Budget: Wood is cheapest for framing. Brick and stone cost more upfront but last longer. Steel is expensive but reduces labor time.

- Maintenance: Do you want to paint every few years? Or prefer something that lasts 50+ years with no upkeep? Brick, concrete, and metal win here.

- Sustainability: Look for materials with recycled content, low embodied energy, and local sourcing. Timber from FSC-certified forests, recycled steel, and fly ash concrete are good choices.

There’s no single ‘best’ material. The right choice depends on what you’re building, where, and why. A beach house in Wellington needs different materials than a warehouse in Auckland. A garage in Rotorua needs different treatment than a basement in Dunedin.

Common Mistakes with Raw Materials

Even pros mess up. Here are the top errors homeowners and small builders make:

- Using untreated lumber for ground contact-leads to rot in 2-5 years.

- Skimping on concrete mix ratios-too much water weakens it. Always follow the bag instructions.

- Assuming all bricks are the same-some are decorative only and can’t bear weight.

- Buying low-grade steel rebar-check for the ASTM or NZS certification stamp.

- Ignoring drainage under slabs-water under concrete causes cracking and heaving.

These aren’t just costly-they’re dangerous. A cracked foundation or failing beam isn’t something you fix with paint.

What are the most common raw materials used in residential construction?

The most common raw materials in homes are wood for framing, concrete for foundations and slabs, bricks or concrete blocks for walls, steel for reinforcement, and glass for windows. Aggregates like sand and gravel are used in concrete and as base layers. Plastics like PVC are used for pipes and window frames. These materials form the backbone of nearly every house built today.

Is concrete considered a raw material?

No, concrete is not a raw material-it’s a manufactured product. Its raw materials are cement, water, sand, and crushed stone. Cement is made by heating limestone and clay. Once mixed, these ingredients react chemically to form concrete. So while you buy concrete as a finished product, it’s made from naturally occurring raw materials.

Are natural materials better than synthetic ones for construction?

It depends. Natural materials like wood and stone are renewable and have low embodied energy, but they can rot, warp, or need more maintenance. Synthetic materials like PVC and composite decking last longer, resist pests, and require less upkeep-but they’re made from petroleum and aren’t biodegradable. The best approach is using each where it performs best: wood for framing, concrete for foundations, and synthetics for moisture-prone areas like bathrooms.

How do I know if the materials I’m buying are up to code?

Look for certification stamps. In New Zealand, timber should have an FSC or NZS 3604 stamp. Concrete mix designs should be tested by accredited labs. Steel rebar must meet NZS 3112. Bricks and blocks should have a compliance mark from the New Zealand Building Code. Always ask your supplier for documentation-not just a receipt. If they can’t provide it, find another source.

Can I reuse construction materials from an old building?

Yes, and it’s a smart move. Reclaimed timber, bricks, steel beams, and even windows can be reused if they’re in good condition. Many demolition companies now sort materials for reuse instead of sending everything to landfill. Reclaimed wood often has tighter grain and more character than new lumber. Reused bricks are cheaper than new ones and give a historic look. Just inspect for damage, rot, or contamination before using.

What to Do Next

If you’re planning a build or renovation, start by listing the materials you’ll need and where they’ll go. Don’t just pick what’s cheapest. Ask your builder or supplier: Where’s this from? Is it certified? How long will it last? What happens if it gets wet?

Visit a local building supply yard. Look at the labels on the lumber, feel the weight of the bricks, compare the texture of different concretes. Talk to the staff-they’ve seen what works and what fails. The right materials, used the right way, make your project safer, cheaper in the long run, and more valuable.